- المنتجات المعدنية منتجات الألومنيوم منتجات النحاس المنتجات المطلية بالمعادن المنتجات الفولاذية المقاومة للصدأ منتجات الفولاذ الكربوني خلط المعادن الخاص

- المشاريع لوحة الحواجز الفولاذية رف الخزانة الهياكل الفولاذية الجسر الفولاذي السقالة المواد الإنشائية المواد الخام الكيميائية One Stop Solutions for Projects

- الحاويات الحاويات القياسية لـ ISO الحاويات للمعدات الحاويات للتخزين والنقل دار الحاويات الحاويات المثلجة الحاويات القريبة السواحل

- الماكينات آلة تشكيل المعادن الآلات الأخرى آلة قطع المعادن آلة تصنيع المعادن آلة التعويج آلة تصنيع البلاط

- منتجات الماكينات صناعة السيارات المنوعات معدات الإرساء معدات السفينة أناء الضغط

- النظام الكهرباء والميكانيكي الكابل الكهربائي الأوتوماتيكي التنسيق الكهربائي نظام طاقة الشمس نظام حماية أمن الكهرباء آلة التحويل خط الأنتاج نظام الإضاءة

- المعدات الطبية منتجات الإطعام منتجات أنبوب إدخال القصبة الهوائية منتجات الرعاية المنتجات البلاسبيكية

- epc مشاريع

- آلات البناء

- خط أنابيب النفط

- خط أنابيب المياه

- انبوب الغاز

- مستلزمات السفن والرباط

- المعادن للزخرفة/ للديكور

- مكونات المحولات

- أنابيب التبادل الحراري

- قطع غيار تكييف الهواء ومستلزماته

- سخان مياه

- أدوات المطبخ و الحمام

- المعادن للأجهزة المنزلية

- أجهزة الطاقة الشمسية

- المصعد الكهربائي

- الأسطح والأسقف

- الكابلات

- الخزانات

- التعبئة والتغليف

- قطع غيار الآلات والمعدات ومستلزماته

- القوالب

- قطع غيار السيارات

- السكك الحديدية و رافعات السكك الحديدية

- تركيب الأجهزة

- الكاشطة

- معدات بناء الطرق

- المكونات الإلكترونية

- اعمال البناء ومواد الديكور

- الأبواب والنوافذ

- الثلاجات

What do you know about bright annealing?

Annealing is an integral part of making materials soft as possible, increase ductility and less brittle. The annealing process reduces the hardness and makes the material easier to machine and can be used on stainless steel, cobalt, chrome, high temperature alloys and titanium.

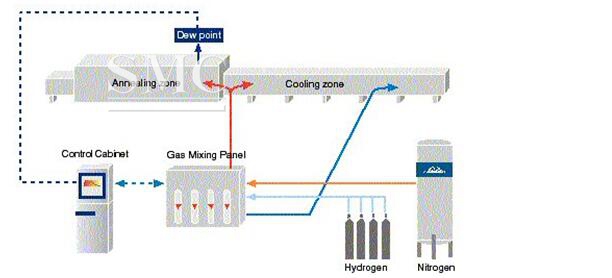

For bright annealing to be effective, tube surfaces must be clean and free of foreign matter. The annealing atmosphere must be relatively free of oxygen (if a bright result is desired). This is accomplished by removing nearly all gas (creating a vacuum) or by displacement of oxygen and nitrogen with dry hydrogen or argon. For common stainless steel alloys, the minimum atmosphere quality required is about -40℃ on a dew point scale (for hydrogen or argon atmosphere).

The matallurgy of bright annealing has been reasonably well defined for some time.

In order to achieve a bright result, the most stable oxide forming element in an alloy in any significant concentration must be reduced at peak temperature and atmosphere quality rather than oxidized. For the common austenitic stainless alloys such as 304L and 316L, the most stable oxide former present in significant concentrations is chromium. As such the oxidation potential of chromium at peak annealing temperatures and atmosphere quality will largely determine whether the stainless will be bright.

Bright annealing is commonly used in the aerospace and medical industries, as well as in military and automotive applications. Vacuum bright annealing produces extremely clean parts, eliminating many steps from the manufacturing process.

theme-font:minor-latin'>℃ on a dew point scale (for hydrogen or argon atmosphere).